Punch Extenders

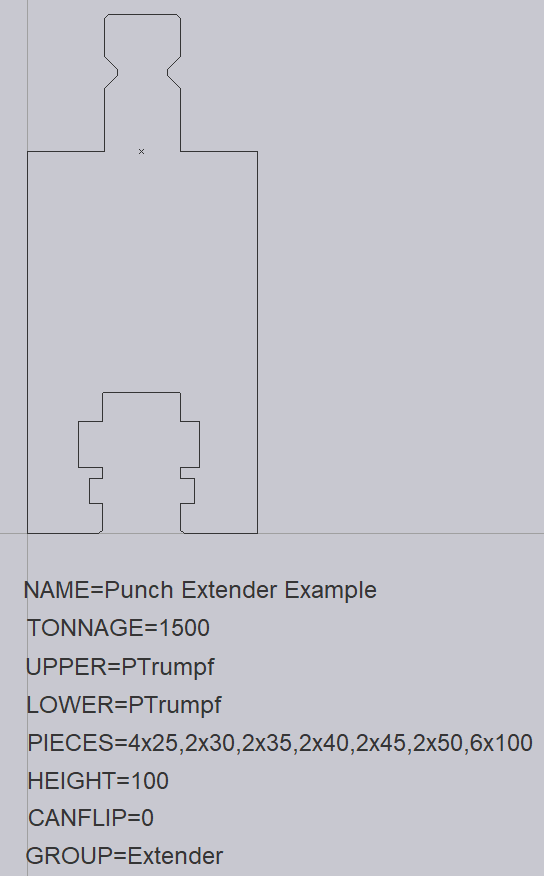

Below, we can see a sample Punch Extender DXF drawing. A side view profile of the tool is drawn. An origin reference point will need to be placed at the mounting point on the side profile of the tool.

The following text entities are required for a Punch Extender:

NAME – This is the name given for the tool.

TONNAGE – This is the tonnage of the tool in kN.

UPPER – This is the upper punch valency of the tool.

LOWER – This is the lower punch valency for the tool that will be inserted into the extender.

HEIGHT – This is the height of the tool measured from the bottom to the mounting point.

INSTALLHEIGHT – This is the available height for the tools to be mounted. This is measured from the bottom of the tool to the inner point of the extender.

PIECES – These are the required tool lengths. These are separated by a comma, and if more than one is required, we can use a multiplier to specify the value required.

CANFLIP – If the tool can be flipped when mounted, this should be set to 1.

GROUP – This can be used to specify the tool group that this tool would belong to. In this case, it is Extender.