How Can We Help?

Assemblies

Preparing an Assembly

- Open an assembly by using File > Open or using the keyboard shortcut O.

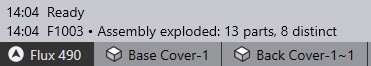

- Use the keyboard shortcut X to explode the assembly. The assembly breaks up into individual bending parts.

- Execute the workflow for the respective bending parts.

After an assembly has dissolved, a message is displayed indicating the total number of parts found in the assembly as well as the number of different parts.

The 3D model is automatically categorised after importing.

| Model | Meaning |

| Assembly | A part depicting an assembly (consisting of different parts or modules). |

| Surface Model | A surface model contains a group of surfaces connected with each other. Some surface models can be analysed and converted into metal parts. |

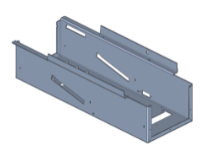

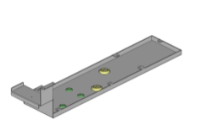

| Metal Model | Models containing layers and bending sections with one and the same sheet thickness. A metal model can be unfolded to one area or used as a basis for bending processing. |

| Laser Model | This is a special type of metal model without bends. Only laser cutting or punching is required for such models. |

| Tube Model | A tube model is created on each of the layers from an extruding tube section with end cuts, rims and holes. |

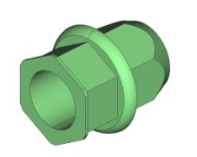

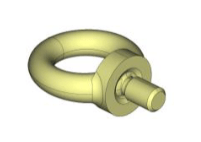

| Component | Depicts a non-metal component such as e.g. a nut, a bolt, or a rivet, … These components are not used for manufacturing processing but only to generate bills of material. |

The symbols are displayed in the software next to the file name. Different colours are displayed in the 3D view to categorise the models. The following standard colours are used:

- Blue-Grey: Surface model, assembly, tube model

- Grey: Metal Model

- Yellow: Components which have not yet been identified

- Green: Components which have already been identified