Pre-Bending

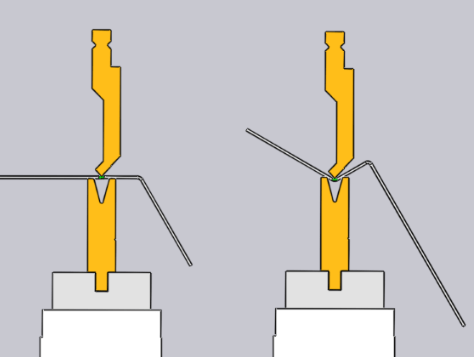

Some collisions can be avoided by splitting a bend operation into a pre-bend and a finishing bend.

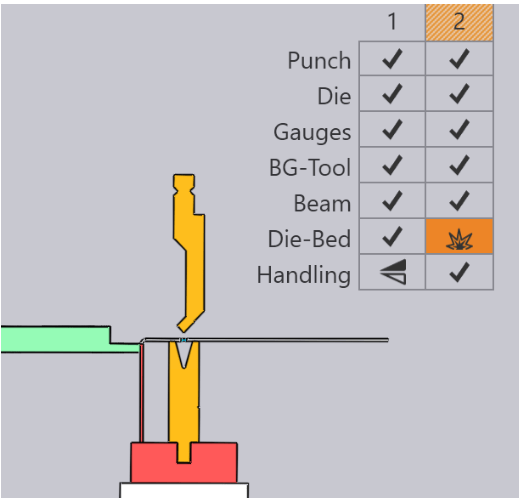

The above part has two bends. On the second bend, the part collides with the die-rail. This cannot be fixed by changing the sequence. One possible fix is to introduce a pre-bend at bend 1, by enabling the Pre-bending checkbox.

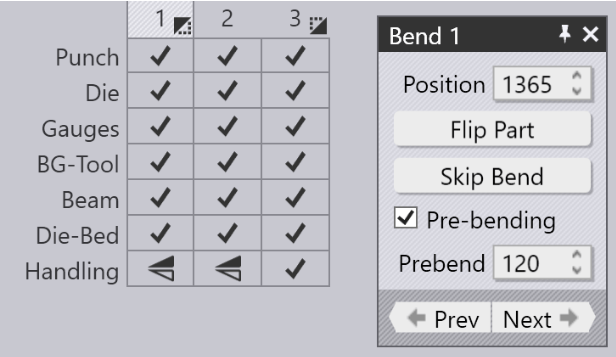

As seen in the image above, the pre-bending checkbox changes bend 1 into a pre-bend and an extra bend is added, bend 3, which is now the finishing bend. The icons on the bend navigator now indicate that bend 1 is a pre-bend, while bend 3 is a finishing bend. In the edit bend glob, the pre-bend input box can be used to fine-tune the angle of the pre-bend. In this example, the angle is set to 120, so the part is bent from the flat state (180 interior angles) to 120 degrees in the first stage, and then to 90 degrees in the second stage. Thus, during the processing of bend 2, the first flange is not fully bent. In turn, this avoids a collision with the die-rail. The images below show the situation when bends 2 and 3 are being processed.