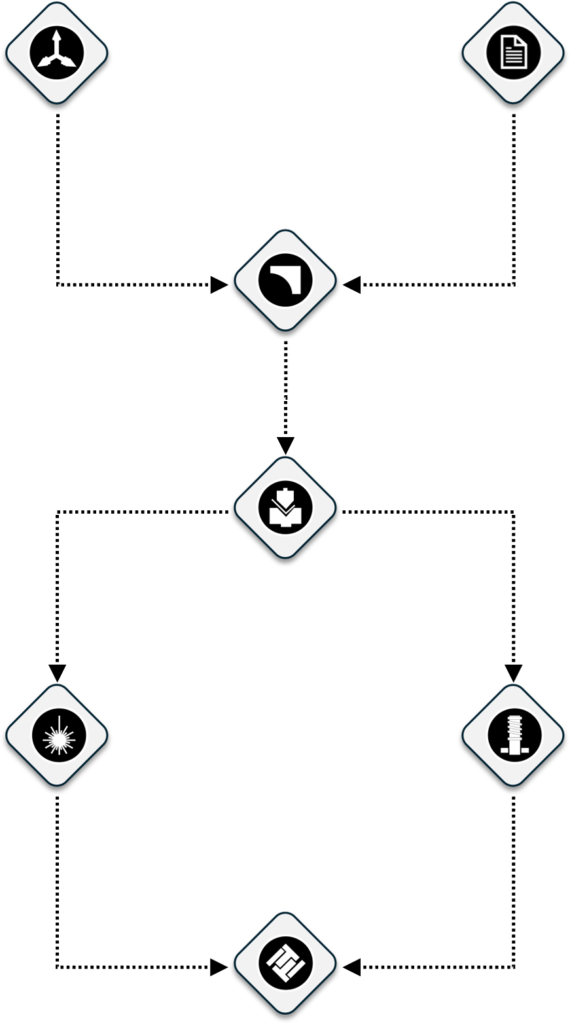

CAD files can be manually or automatically uploaded and are fully validated before further processing, any problems are highlighted such as material allocation and clearly shown.

Orders can be impored manually or automatically and once imported will validate availble parts and will clearly highlight any issues with missing CAD / Part files.

By default all data is stored into central SQL databases.

the bending oprtation will take the verified CAD files and use customers tools and default settings to produce a bend solution and a detailed flat pattern. Any problems are clearly highlighted.

Once detailed flat patterns are generated they are passed to any 2D CAM machines Punch / Laser for automatic tooling.

TRUMPF Flux clearly displays all types of information about the part, from basic part data to complete built in simulations. Part data can also be exported out into excel based files.

Based on the workflow assignment the parts are then nested up with the nest sheet results clearly displayed.

Code export will send out the NC code to the correct machines ready for the operator.

TRUMPF PRAXIS follows a logical workflow approach to help ensure that the programmed parts are compatible with the down streaming process. TRUMPF PRAXIS fully validates the process and will stop next stage automatic processing in case of an error whilst also giving alerts to potential problems.