Auto Sequence

Inside the Punch tab, navigate to the Auto Sequence icon.

This command is used to sequence the tooling in the part for generating the NC code. The sequencing is done using the settings in the Auto Sequence page of the Part Settings dialogue.

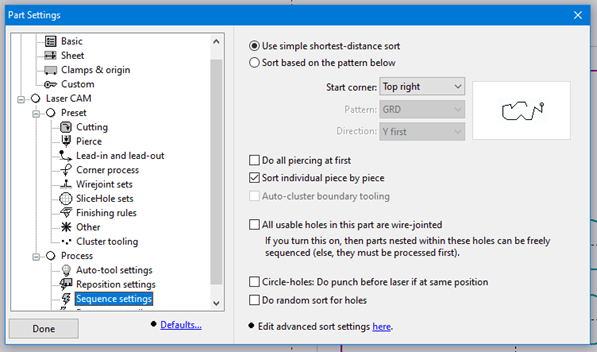

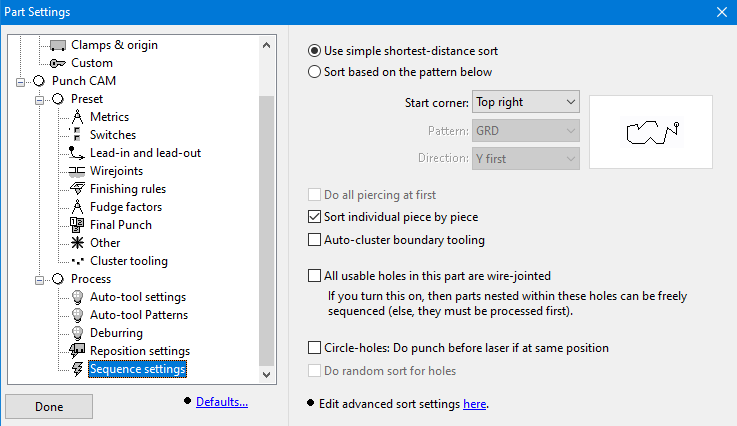

Sequence Settings

The settings on this page control how the tooling is sequenced. Typically, tooling is sorted by working frame first, and then sorted so that inner tooling (holes, slugs) is processed before outer tooling (outer boundary of the part).

Use simple shortest-distance sort: Tooling is sorted starting from the specified corner and using the shortest-distance-next algorithm. If you turn this setting off, MetaCAM sorts tooling using an imaginary grid, defined below.

Start corner: Set up the start corner of sequencing, for both the shortest-distance sort and the grid-based sort.

Pattern: If a shortest-distance sort is not used, MetaCAM builds an imaginary grid, and sorts tooling according to which cells of the grid they lie in. The pattern parameter lets you choose whether the tooling is sorted in a GRD (serpentine) pattern, or an LAA (linear) pattern. The picture of the sort result that appears near this list shows you the exact meaning of the sort options you have chosen.

Direction: Let you choose whether the sequence starts off in a horizontal or vertical direction.

Do all piercing at first: This setting is available only for laser and hybrid machines. If turned on, all the piercing for all laser cuts is done first, followed by the actual cutting of the laser contours.

Sort individual piece by piece: Some drawings consist of several disjoint pieces. When processing such multi-piece parts, you can turn on this setting to force MetaCAM to finish processing one piece before going to the next. Without this setting on, MetaCAM can process the holes in all pieces first before going on to process their outer boundaries.

Auto-cluster boundary tooling: This setting is available only for punch machines. If turned on, the tooling around the outer boundary of the part is automatically grouped together into cluster punches for more effective sequencing.

All usable holes in this part are wire-jointed: If you turn this on, then parts nested within these holes can be freely sequenced. Else, they must be processed first.

Circle-holes Do punch before laser if at the same position: Enabling this will process punch tooling before laser tooling for holes in a part if they are at the same position.

Do random sort for holes: Enabling this will sort the holes into a random order, rather than one after the other.

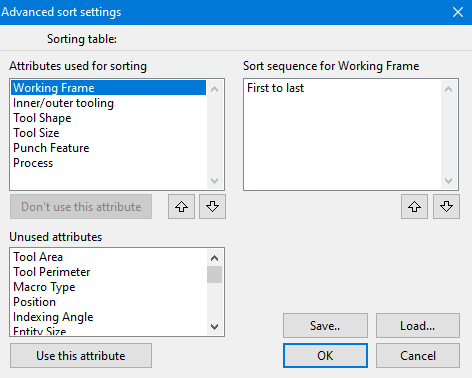

Advanced: Clicking on this button brings up the Advanced Sort Settings dialogue. You can use the various sort attributes in this dialogue to group the tooling before it is processed by either the shortest-distance sort or the grid-based sort explained above. For typical applications, one would use the “Working frame” and the “Inner/outer tooling” attributes. Other attributes could be useful in specialized situations.